Here are the top features with pros and cons of the newly-developed EV Skateboard platform

Nowadays almost every new electric vehicle going to customers is built on the dedicated EV platform, called the Skateboard Platform. It is designed to use the maximum space by putting the batteries at the bottom and optimizing the space with a flat floor design. It offers more flexible design options and does not require the ICE vehicles’ components making it easier to customize.

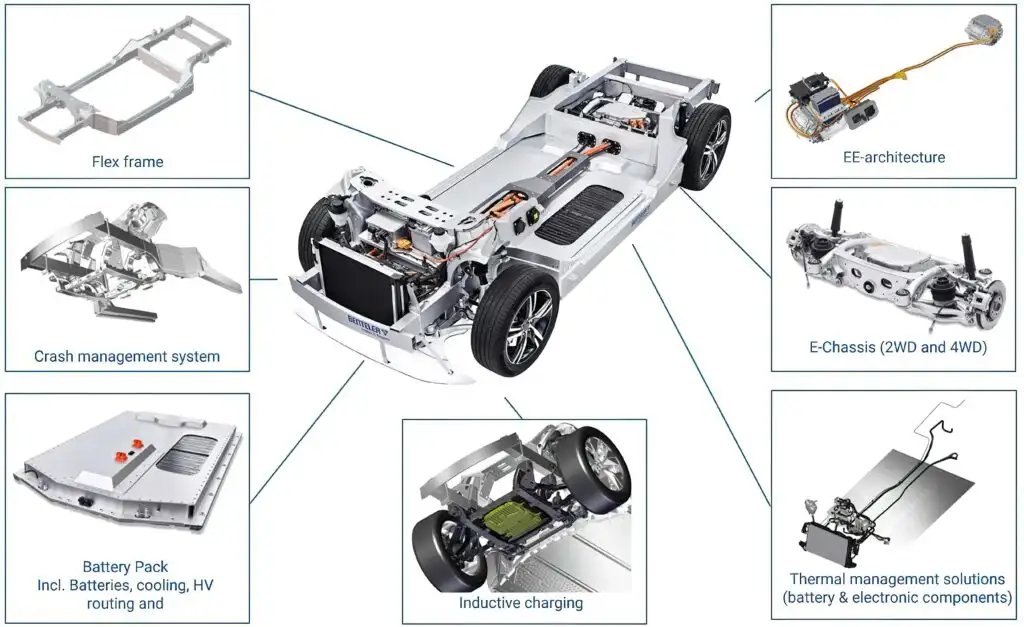

EV Skateboard Platforms Key Features

In this platform, the batteries are usually placed under the floor and the electric motors are mounted between the wheels helping it to increase the wheelbase. This method creates space for passengers and cargo while keeping a low centre of gravity which results in enhanced vehicle stability. These EV skateboard platforms are highly modular allowing the OEMs to design and customize them accordingly and shape them for various vehicle types.

This platform requires a lot of capital to design, engineer and manufacture, but once this process is completed, the manufacturers can make various types of vehicles with little tweaks and mass produce them which reduces the overall cost of manufacturing. Another feature of this platform is enhanced safety and reliability due to its structural integrity helping it absorb collisions and other mishappening and keeping the passengers safe.

Types of Electric Skateboard Platforms

These new EV skateboard platforms are designed to offer more space both for passengers and cargo. The Skateboard platforms are also used in developing other vehicle types such as trucks and minibuses for streamlined production and meeting scaling requirements. These platforms can be easily scaled to support larger vehicle types such as semi-trucks.

Types of Platform Chassis in Skateboard Platform

Monocoque Chassis:

Its lightweight design offers seamless integration of both the car’s body and its mechanical components, offering a simple build and sturdy build that can be easily scaled for mass production of these vehicles.

Ladder Frame:

This platform is suited for off-road vehicles helping them to offer traditional design aesthetics and results in better performance and flexibility to match the terrain type. It comes with two long beams and is easier to produce.

Backbone Frame:

Next comes the Backbone Frame which uses a stiff, rectangular tubular backbone that connects the front and rear suspension. This chassis type offers a better build but at a higher cost as it is more expensive to produce.

Space Frame:

The Space Frame chassis is made of triangulated tubes and is attached with body panels to create a lightweight and rigid structure, offering both robust strength with lightweight construction for better weight distribution.